Metal inert gas mig welding.

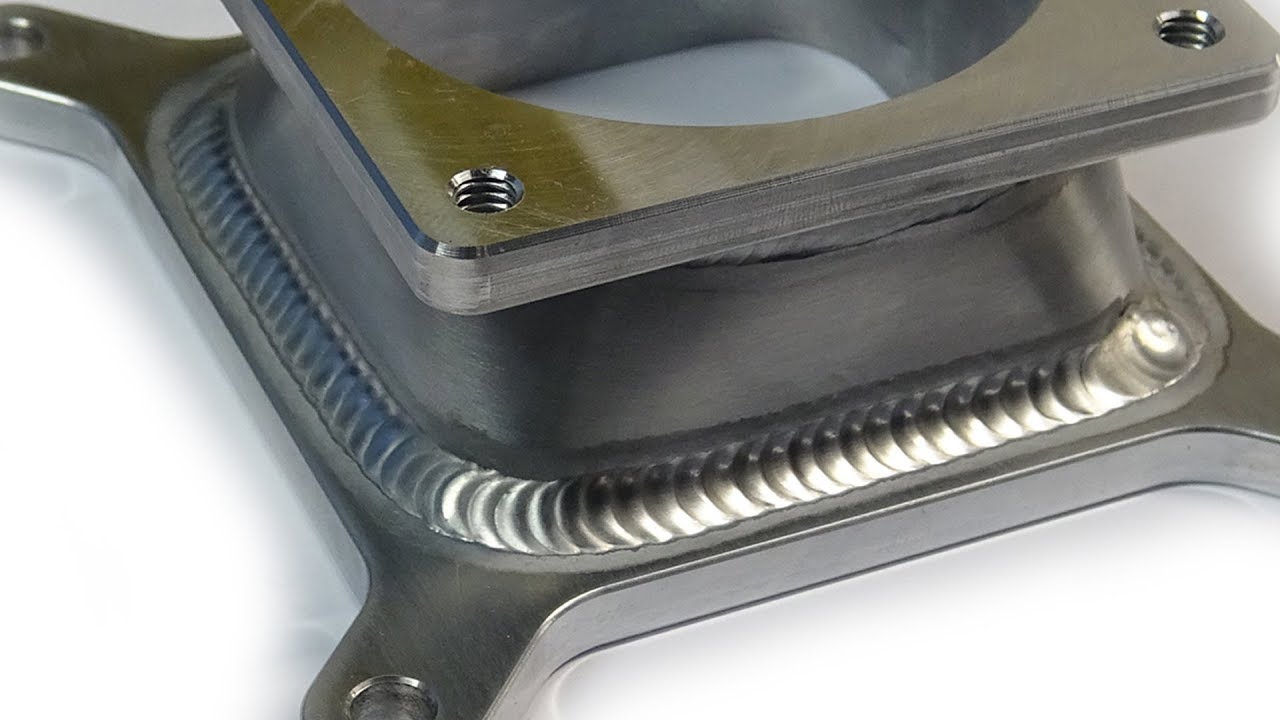

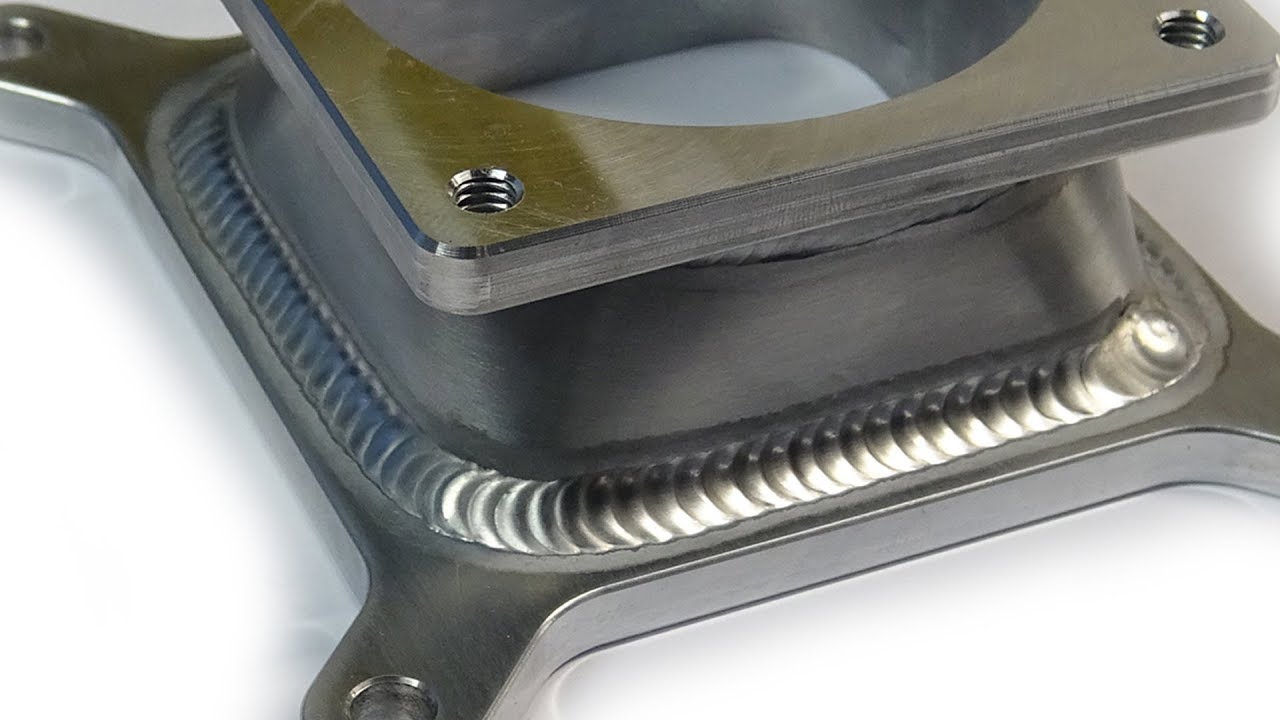

Tig tack welding sheet metal.

Formally known as gas metal arc welding mig welding uses a tool to feed metal wire into the weld puddle while an electrical arc melts the wire which will fuse to the base metal upon cooling.

Tig welding for sheet metal using a tig welders means that one can work on materials of 26 gauge.

Tungsten inert gas tig welding.

Purging is needed if your welding stainless or nickel alloys and titanium a little scale is normal on the back of the weld but it sounds as though your overheating the metal very easy to do on thin material.

Using this process enables more than effective work on thin materials as it provides high precision and high quality work.

Formally referred to gas tungsten arc welding tig welding is a similar process mig.

To meet these challenges kemppi has developed a tack welding feature microtack for thin sheet components made of carbon and stainless steel and titanium with thicknesses of up to 4 mm.

Tungsten inert gas tig welding.

Metal inert gas mig welding.

Formally known as gas metal arc welding mig welding uses a tool to feed metal wire into the weld puddle while an electrical arc melts the wire which will fuse to the base metal upon cooling.

That will keep your joint from spreading on you while welding.

The mophorn tig welder is best for sheet metal stainless steel copper brass and titanium.

Use a hammer to tap all the spots that aren t tacked together.

The diameters down to 020 040 and 1 16 inch tungsten are popular.

If you are using mig it s best to weld vertically down.

With mild steel there is no need to flow argon over the back of the weld purging or backgassing are the usual terms.

When welding sheet metal you re going to want to tack your joints every 1 5 to 2 inches.

It has a fantastic quality that provides you to hold the current for more than 10 seconds.

Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten.

The feature is available in kemppi s mastertig mls acdc models and the new generation mastertig series.

Formally referred to gas tungsten arc welding tig welding is a similar process mig.

Ceriated tungsten are preferred with thoriated tungsten as a second option.

Tig welding sheet metal forget the larger 1 8 inch tungsten electrode and use a smaller one.