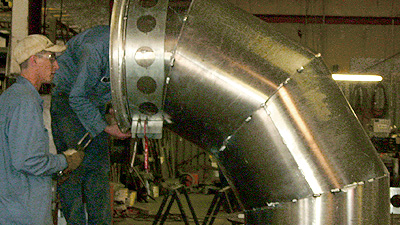

We find tig welding often used for welding critical joints welding a variety of metals including mild steel and tig welding also works well for small metal areas.

Tig welding galvanized mild steel sheet metal.

They were made from galvanized sheet metal and we didnt clean crap.

Tig welding for sheet metal.

But using this method also requires some practice and practice advice in order to understand it.

You can also utilize the tig process to weld corten.

Below are a few recommendations on how to weld on galvanized steel.

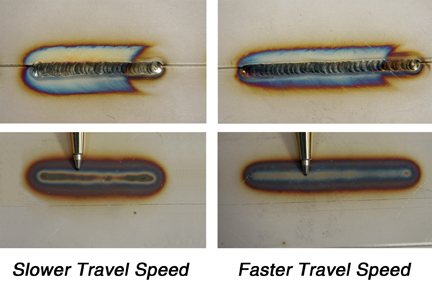

Work slowly around the exterior edge on the metal itself moving forward 2 3 inches 5 1 7 6 cm before bringing your welding rod back over the surface you just covered.

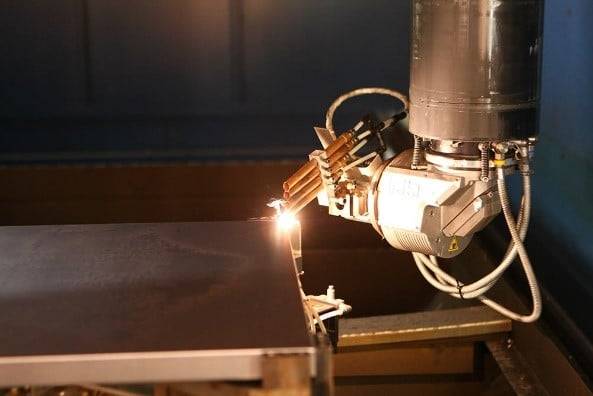

Using this process enables more than effective work on thin materials as it provides high precision and high quality work.

For mild steel to stainless i would use 2 thoriated or ceriated electrodes.

The galvanized layer can be removed by grinding down to the bare metal but if you miss any it will make the welding difficult.

It s recommended to use a 023 or 024 inch wire for most light gauge sheet metal work.

Subscribe for new videos every monday and friday.

We just welded em.

3f lap joint tig welding 11 ga carbon steel.

Galvanized steel welds similar to uncoated carbon steel when properly prepped.

The joy of tig welding galvanized steel i m afraid.

When the material is 18 gauge and thicker you may be able to use a 030 inch wire.

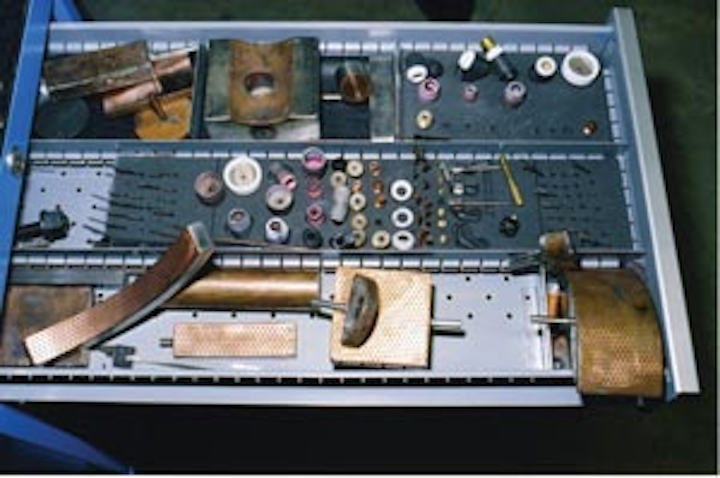

Manufacturers of filler metal have come up with special wires that promise to eliminate porosity.

When welding weathering steel you follow the same primary guidelines that you need to follow for mild steel.

To weld mild steel choose an american welding society classification wire such as er70s 6 which has a weld puddle that wets out nicely.

He asked that we demon.

The most common welding rods for mild steel are the e60xx and e70xx line.

Using a tig welders means that one can work on materials of 26 gauge.

Video shows arc shots and tips for tig welding a 3f lap joint on 11ga carbon steel.

Https goo gl frdnss this video was by special request from a viewer arcstreams.

In tig welding you use a tungsten electrode in combination with separate filler wire.

If you attempt to weld galvanized steel without removing the galvanizing from the weld area the weld puddle will pop blow out and create a health hazard to the welder and any individuals in the immediate area.

Sep 02 20 05 23 pm.

To weld a tear or split in galvanized steel start on any edge of the metal.

Welding galvanized metal is too risky.