We ve heard all of the tricks in the book but none of them completely stop the warping.

Tig welding sheet metal without warping.

The best two electrodes for welding auto body sheet metal is either ceriated tungsten or thoriated tungsten.

When welding thin metal the main objective is to avoid warping burn through and excessive heat affected zones while still ensuring the weld has enough mechanical strength for the application.

Only reduce or control it.

This is especially helpful if you re welding in an area that is very critical and could lead to oil canning.

Tig welding tips questions equipment applications instructions techniques tig welding machines troubleshooting tig welding process 12 posts page 1 of 1 settings for thin sheet metal.

Another alternative is to surround the area you re welding with an anti heat compound that will block the heat from spreading to the rest of the panel and potentially reduce warping in the panel.

Learn why mig pulsed mig tig and pulsed tig are the ideal choices when welding sheet metal.

So here are 11 ways to prevent sheet metal from warping in tig welding.

The secret is that the heat and cooling from welding will shrink the metal around the weld seam to some degree.

Use clamps to control expansion.

Fix problems before they permanently set.

Correctly sizing a weld not only minimizes distortion but also saves weld metal and time.

Limit the number of passes.

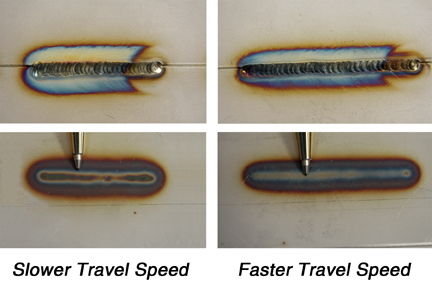

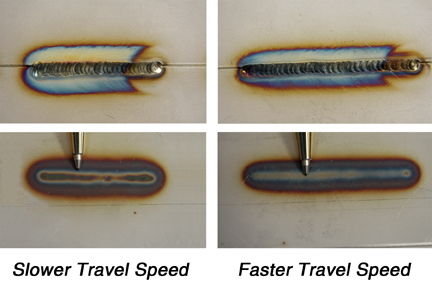

The bigger the weld the greater the shrinkage.

The fact is that no matter how good or careful you are metal will warp when you re welding on sheet metal.

Short circuit transfer mig short arc tig and pulsed tig welding processes provide the most control over the heat to address these challenges.

Ditch a 1 8 inch tungsten electrode for something much smaller like 1 16 inch tungsten.

Use intermittent welds instead of continuous welds where possible to minimize the amount of weld metal.

Because it will have you a lot more control over the whole process and it is more forgiving in case you do anything wrong.

Minimize the amount of heat put into the weld.

Here s a list of tips that help reduce warpage in sheet metal fabricaitons.

Intermittent rather than continuous welds help as does minimizing the amount of filler metal used.

Design and welding should be addressed to minimize this sort of warping.